Poland Covered Bridge Rehabilitation: 2003-2004

[WGN 45-08-02]

Poland Bridge Rehabilitation Index

- Poland Bridge Rehabilitation Work Begins: June 2003

- Poland Bridge Rehabilitation Work Continues: July 2003

- Poland Bridge Rehabilitation Work Continues: August 2003

- Poland Bridge Rehabilitation Work Continues: September 2003

- Poland Bridge Rehabilitation Work Continues: October 2003

- Poland Bridge Rehabilitation Work Continues: November 2003

- Poland Bridge Rehabilitation Work Continues: January 2004

- Poland Bridge Rehabilitation Work Continues: February 2004

- Poland Bridge Rehabilitation Work Continues: March 2004

- Poland Bridge Rehabilitation Work Continues: April 2004

- Poland Bridge Rehabilitation Work Finished: July 2004

- Poland Bridge Rehabilitation Inspection Issue Addressed: July 24, 2004

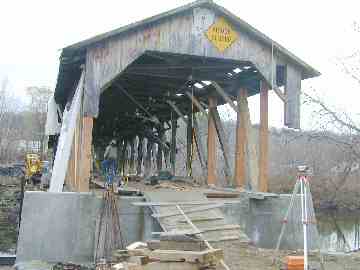

The Poland Covered Bridge Update: June 2003

Work Resumes on Poland Bridge

June 23, 2003 - The rehabilitation of George Washington Holmes' arch bridge has begun. The first step in the process has been to sink pilings into the bottom of the Lamoille River to support the old span while critical work is done--that of overhauling the trusses and restoring the camber lost over the years. Currently, the bridge is sagging about 18 inches. Restoration requires that the trusses be tightened up for a healthy camber of plus 12 inches, raising the center of the sagging 140-foot span approximately 30 inches.

The contractor, Alpine Construction of Stillwater, NY, opted to rehabilitate the bridge over the river using scaffolding rather than lifting the bridge off its abutments and doing the work off river. The plan to put scaffolding under the bridge required that supporting pilings be driven. Much to everyone's surprise, the pilings had to be driven some 140 feet into the river bottom to find bedrock.

The rehabilitation plan requires that the bridge will support light automobile traffic, and that the historic fabric of the trusses will be retained to the greatest extent possible. There will be a new roof, siding, and deck. Curb timbers will leave walking space for pedestrians on both sides of the roadway.

For a history of the bridge and the work done to save it, visit "Stabilization Work Complete" and "2nd Phase Planning to Begin". Also see the Historic Bridge Committee Minutes for July 17, 2001 and March 21, 2002.

Photo by Joe Nelson

June 23, 2003

Photo by Joe Nelson

June 23, 2003

Photo by Joe Nelson

June 23, 2003

The Poland Covered Bridge Update: July 2003

July 7, 2003 - As the rehabilitation of the Poland Bridge continues some questions have been raised about the disposition of the bridge, according to contractor Alpine Construction's foreman Jim Ligon.

The contractor advises that the bridge was not raised high enough over the abutments during the stabilization phase performed in the early spring of 2001 and should be raised higher. The south end of the bridge was found to have been shifted four inches down stream as a result of high water on June 15, 2002 despite the bridge having been raised three feet higher over the stream.

The contractor also advises that the bridge, when completed, should not be opened to light traffic as planned, but should be restricted to cycles and pedestrians. The proposed three-ton limit can be challenged by many of today's SUVs, Ligon said.

Work continues toward the objective of overhauling the trusses and restoring the lost camber. As a first step, the south end of the bridge was leveled on the abutment, raising the down-stream side approximately three inches.

The work will be done while the bridge remains on the river supported by steel pilings. No core was taken under the bridge to find bedrock for the pilings, said Ligon, but a measurement was taken at the railroad bridge down stream and "refusal" was found to be 25 feet. When that pilings were driven at the Poland Bridge, three lengths, or 140 feet of piling were joined to reach refusal at 102'6" below the river bottom.

Photo by Joe Nelson

July 7, 2003

Down-stream side. Three-inch leveling timbers can be seen.

Photo by Joe Nelson

July 7, 2003

Poland Bridge Raised

July 14, 2003 - The Poland Bridge now stands higher over its abutments than it did on June 15, 2002 when high water reached the bridge and moved it down stream four inches. The next step in the rehabilitation, according to Alpine Construction Foreman Jim Ligon, will be bracing the bridge with steel beams to support it while the chords and trusses are worked on to tighten the structure and restore the lost camber. All of the historic fabric still serviceable will be retained, Ligon said.

The racking will be corrected, the stretched splices in the bottom chords will be mended, the Burr arches will be restored to the face walls of the new abutments, and the bracing timbers in the end panels will be removed. The stabilization bracing evident at the upper chords will probably remain, said Ligon. There will be a new roof and siding.

Photo by Joe Nelson

July 14, 2003

Up-stream side. Additional members in the cribbing raise the bridge an additional two feet.

Photo by Joe Nelson

July 14, 2003

Down-stream side. A hydraulic jack is hiding in the center of the cribbing.

Photo by Joe Nelson

July 14, 2003

This under-side view shows the reversed camber. Steel cross-beams will be inserted and the sagging bridge will be jacked up into position for repair. The distribution beam above right will be removed, the under-floor crossbeams will be restored.

Photo by Joe Nelson

July 14, 2003

A view through the bridge. The new deck will be glu-lam. Curbing will provide space for pedestrians on both sides of the bridge.

The Poland Covered Bridge Update: August 2003

August 5, 2003 - The trusses have been leveled, the racking removed and the camber set to 18 inches, supported on the steel staging. An 18-inch downstream hook has been removed, straitening the bridge. The additional bracing installed in the end-panels during the stabilization phase has been removed.

The bridge has been moved 10 inches back upstream, restoring its position on the abutments to where it was before the June 15, 2002 high water. The bridge had been raised an additional three feet above the abutments to accommodate the installation of the supports used to set the camber. This additional cribbing has been removed and the bridge now sits at the height above the abutments set at the completion of the stabilization stage.

Further adjustment to the truss is required, as now most of kingpost braces appear to be too short to support the current configuration by as much as four inches. Note also, the lower ends of the bottom kick braces have broken loose from their fastenings on the tops of the bottom chords--the upper kick braces are dangling from the upper chords.

Photo by Joe Nelson

August 5, 2003

Down-stream side with 18 inches of camber.

Photo by Joe Nelson

August 5, 2003

Down-stream side. Detail, lower chord between 1st and 2nd panels.

Photo by Joe Nelson

August 5, 2003

Down-stream side. Detail, lower chord at 2nd and 3rd panels.

Photo by Joe Nelson

August 5, 2003

Down-stream side. Detail, upper chord between 2nd and 3rd panels.

August 18, 2003 - The new abutments are under construction. The new build features back-walls to separate the road-bed from the bridge seating platform. The original abutments allowed the road bed to contact the ends of the bottom chords causing rot.

The "face wall" of the new abutments will be fitted with steel brackets to receive the ends of the Burr arches, which will be restored to the bridge's original configuration. The steel brackets will isolate the wooden arch-ends from contact with the abutment where rot-inducing moisture can be picked up.

The problem of the "too-short" king post braces will be solved through the use of shims rather than replacing the braces, which are part of the historic fabric.

Photo by Joe Nelson

August 11, 2003

The forms are set for new abutment cap and back-wall

Photo by Joe Nelson

August 11, 2003

End of chord cut off to clear concrete forms. The bottom chords are to be replaced.

The Poland Covered Bridge Update: September 2003

September 22, 2003 - As work on the abutments nears completion repair and replacement of the floor beams and braces continues. A temporary deck will be laid on the floor beams for use as a platform to allow work to go forward on the truss and roof system.

Eighteen cracked, broken or rotted king posts and 21 chord-pieces will be replaced, work to begin with the arrival of a timber shipment.

The problem of the "too-short" king post braces will be solved through the use of shims rather than replacing the braces, which are part of the historic fabric.

Photo by Joe Nelson

Aug. 11, 2003

Timbers marked with a red ribbon will be replaced.

Photo by Joe Nelson

Sept. 22, 2003

Newly built south abutment awaits a new cap and backwall.

Photo by Joe Nelson

Sept. 22, 2003

Glu-lam floor sections stacked and ready for installation.

The Poland Covered Bridge Update: October 2003

October 14, 2003 - Reconstruction of the truss has begun at the north end of the bridge.

Photo by Joe Nelson

Oct. 14, 2003

Two new kingposts of the 18 slated for replacement have been assembled into the truss at the north-east corner.

Photo by Joe Nelson

Oct. 14, 2003

A detail view of the kingpost connection to the lower chord. Note that the lap-cut post fits into shoulders cut into the chord members.

Photo by Joe Nelson

Oct. 14, 2003

The outer chord-end members have been removed and the new kingposts installed. Both the outer and inner chord end-members here will be replaced.

Photo by Joe Nelson

Oct. 14, 2003

Chip Ligon of Alpine Construction prepares the new chord end-members for installation. Note the tension splice and the lapping for the kingposts in the spruce timber.

The Poland Covered Bridge Update: November 2003

November 6, 2003 - Reconstruction of the truss continues at the north end of the bridge and has begun on the south end.

A slight delay was caused last week when heavy rains brought the Lamoille River out-of-banks making it difficult for the construction crew to move around the bridge. The surrounding fields and roadway were under water. The water level actually came within seven-inches of reaching the bridge, said Jim Ligon, construction foreman.

The crew is working hard to retain as much of the historic bridge fabric as possible. However, as work proceeds, more rot and damage is being uncovered requiring original wood to be replaced by new. A case in point, noted Ligon, an earlier reconstruction altered many of the knee-braces: The tenons were cut off and the knee-braces were reinstalled with nails. This contributed to the severe racking found on the bridge, Ligon said.

Photo by Joe Nelson

Nov. 6, 2003

The first three panels of the north end of each truss are very nearly completed.

Photo by Joe Nelson

Nov. 6, 2003

Note the replaced knee-braces, correcting a problem caused by a prior reconstruction.

November 21, 2003 - The rehabilitation of the Poland Bridge is proceeding well. According to Jim Ligon, construction foreman, the work is ahead of schedule in spite of repeated heavy rains and high water.

Chord replacement at three of the four corners of the bridge is completed, said Ligon. He expects work on the southwest corner chord to be finished Monday. Two chord members in the center of the bridge and five kingpost replacements remain to be done, he said.

New bed timbers will be placed under the chords at the abutments and the end timbers of the Burr Arches will be replaced to terminate at the face-walls.

Work was stopped October 28 when the Lamoille River went out of banks and forced the construction crew to move equipment to high ground. The rains came again on November 18 causing the river to rise once more, peaking on November 20, the waters rising to within 14 inches of the center of the steel scaffolding supporting the bridge. Construction equipment at the north end of the bridge had to be moved again, including the trailers. Stacks of bridge timbers, floating away, had to be lassoed and tied to trees. The approach road to the north end of the bridge was washed out.

Photo by Joe Nelson

Nov. 21, 2003

Flood waters came within 14 inches of reaching the steel beams supporting the center of the span.

Photo by Joe Nelson

Nov. 21, 2003

High water is marked by the mud-line on the steel beam at the north abutment.

Photo by Joe Nelson

Nov. 21, 2003

Where the original diagonals, or king-post braces are too short as a result of re-cambering the bridge, a shim has been inserted.

Photo by Joe Nelson

Nov. 21, 2003

A view of the south end of the bridge. Three of the of the four end-panels and chords are completed.

The Poland Covered Bridge Update: January 2004

January 26, 2004 - The structural rehabilitation of the Poland Bridge is very nearly complete as the crew continues work under sub-zero conditions.

According to Jim Ligon, Alpine foreman, the plan is to begin removing the steel girders supporting the bridge next week, at which time the bridge will support itself.

All that is left to do structurally is to complete the replacement of the end sections of the Burr Arches at the south end of the bridge, Ligon said. The new floor is being installed from the north end and should be completed shortly. The roofing won't be installed until after the bridge structure settles when the steel supports are removed. The siding will be replaced at that time.

Photo by Joe Nelson

January 26, 2004

A view of the Poland Bridge from the south end on the down-stream side. Work continues in sub-zero conditions.

Photo by Joe Nelson

January 26, 2004

This up-stream view shows some of the crew fitting a new end segment to the Burr Arch.

Photo by Joe Nelson

January 26, 2004

A view of the end panels of the up-stream truss, south end. Note the end of the Burr Arch waiting to receive the end segment section.

Photo by Joe Nelson

January 26, 2004

A view of the end panels of the down-stream truss, south end. Note the end of the Burr Arch waiting to receive the end segment section

Photo by Joe Nelson

January 26, 2004

The Burr Arches at the north end of bridge are fully installed. Notice that the end of the arch is received at the abutment face-wall by a galvanized steel receptical.

Photo by Joe Nelson

January 26, 2004

This view of the down-stream side of the north end of the bridge shows more of the Burr Arch segments.

The Poland Covered Bridge Update: February 2004

Poland Bridge Stands on its Own

February 2, 2004 - Last Friday noon, January 30, the wooden blocks supporting the Poland bridge on the steel-girder scaffolding were removed. From that time George Washington Holmes' trusses are again supporting the structure just as he meant them to 117 years ago.

Before the blocks were removed and the bridge was supported by the steel scaffolding, the camber of the span measured 17 inches. According to William Flanders, VAOT site engineer, When the blocks were removed and the trusses assumed the weight of the span, the camber was reduced by only one and one-half inches, to 15.5 inches. Flanders will continue to monitor the camber by means of a transit as the timbers continue to settle under the weight of the structure, and as the dead load of curbing, running planks and siding are added to the bridge.

Prior to the reconstruction the camber was a negative 18 inches.

Currently, the curbing is being assembled on the new laminated bridge floor -- the curbing will consist of a 4x6 spruce rail supported at intervals on two stacked 4x6 blocks of treated wood, the assembly bolted through the floor. Next, the oak running planks will be installed over the laminated floor followed by the addition of the siding. The roofing will go on last when the bridge dimensions have stabilized.

The steel scaffolding is scheduled for removal this week

Photo by Joe Nelson

February 2, 2004

Poland Bridge Stands on its Own with 15.5" of camber.

Photo by Joe Nelson

February 2, 2004

A view of the new Burr-arch end-segments at the south end of the bridge, down-stream side.

Photo by Joe Nelson

February 2, 2004

A view of the interior of the bridge with the reconstructed structure.

February 7, 2004 - The new curbing has been installed leaving a roadway 9 feet 8 inches wide. With this addition to the bridge dead-load and a week in which the timbers have been settling under the weight of the structure, the camber has decreased two-and-one-quarter inches to 14 3/4 inches.

Next, two-inch oak running planks will be laid down in the roadway to protect the laminated flooring. The runners will each be 40 inches wide.

Steel clamps will be installed to hold nailers in preparation for the new siding. The roofing will go on when the structure has adjusted to this additional dead-load and the camber has stabilized.

By mid-day Monday most of the steel scaffolding has been removed, an essential step as spring approaches--when the ice begins to move, the scaffolding standing in the river bed could have caused an ice jam dangerous to the bridge.

Photo by Joe Nelson

February 7, 2004

By mid-day Monday most of the steel scaffolding has been removed.

Photo by Joe Nelson

February 7, 2004

The new curbing has been installed leaving a roadway 9 feet 8 inches wide.

February 20, 2004 - Work is going forward on the Poland Bridge as the siding is applied, the downstream side being nearly completed. When the siding is finished the oak runners will be installed and the roofing put on.

The camber appears to be holding at very nearly last weeks measurement of 14 3/4 inches.

Photo by Joe Nelson

February 20, 2004

The siding is nearly complete on the downstream side.

The Poland Covered Bridge Update: March 2004

March 11, 2004 - Work on the Poland Bridge nears completion as the upstream side of the roof receives its new steel standing seam roofing, leaving the downstream slope still to be done. The siding is all installed except for around the south portal. The oak running planks are prepared and laid out in the bridge ready for installation over the new floor.

With very nearly all of the dead-load on the trusses, the camber, according to Alpine foreman Jim Ligon, is holding at 14 and 1/8 inches. Work on the bridge itself should be largely completed by the middle of next week, he said.

Alpine Construction is under contract to construct the bridge approaches and pave the roadway in the immediate vicinity of the bridge ( the rest to be completed by the Town of Cambridge).

Photo by Joe Nelson

March 11, 2004

Roof work is underway. The siding is complete except for near the south portal. Note the camber along the bottom edge of the siding.

Photo by Joe Nelson

March 11, 2004

The rise of the restored camber can be seen in this interior view. In the foreground oak running planks are laid up in the bridge ready for installation.

March 30, 2004 - Work on the Poland Bridge should be finished today, said Jim Ligon, Alpine foreman. What remains to be done, he said, is to complete work on the soffits and on the running planks. The camber, with all of the dead-load on the trusses, remains unchanged at 14 and 1/8 inches.

Work will begin on the bridge approaches in mid-April when the frost is gone out of the ground and the soil has stabilized, Ligon said. Alpine Construction is under contract to construct the bridge approaches and pave the roadway in the immediate vicinity of the bridge, the rest of the road work to be completed by the Town of Cambridge.

Photo by Joe Nelson

March 30, 2004

With the siding and roofing of the bridge completed, less than a day's work remains. The gable-end soffits get finishing touches.

Photo by Joe Nelson

March 26, 2004

One of the last jobs to be done, the oak running plank installation is very nearly completed.

The Poland Covered Bridge Update: April 2004

April 1, 2004 - Pictures being worth a thousand words, Jim Ligon, Alpine Construction foreman, has sent along some of his photos to show some of the final touches completing the restoration of the Poland Covered Bridge.

A new bit of covered bridge trivia - With the reconstruction work complete, the Poland, or Cambridge Junction Covered Bridge, is the only Burr Arch span in Vermont where the arches act upon the faces of the abutments. The arches in all of the others terminate near the ends of the lower chord. (The arches in the Pulpmill Bridge in Middlebury/ Weybridge also act upon the abutment face-walls, but the Pulpmill Bridge uses a laminated arch, not a Burr Arch.)

Photo by Jim Ligon

April 1, 2004

On upstream side looking north. Windows cut, siding following the top of the arch.

Photo by Jim Ligon

April 1, 2004

Arch bearing plate is hidden behind siding. The cover to the right of the "birdhouse-like" cover hides an arch through-bolt.

The Poland Covered Bridge Update: July 2004

Cambridge Junction Bridge Inspection Results Iffy

By Joe Nelson

Cambridge Junction, July 3, 2004 - The acceptance inspection of the Poland Bridge took place on Wednesday, June 30, with acceptance assured. However word was received today that further investigation was needed due to a distortion of the bearing plates that receive the arches at the bridge abutments.

A satisfactory inspection is necessary for the bridge to be accepted into the state highway system and open to traffic. With the bridge closed, the planned opening ceremony for July 4 would have to take place without access to the bridge.

According to Jim Ligon, Poland Bridge construction supervisor for Alpine Construction, Bill Flanders, the AOT resident engineer, called him late Friday morning and informed him that someone from AOT had determined 11th hour that the bearing plates behind the arches are bent and the opening ceremony cannot take place without correcting that.

No plan was submitted on the correction desired, other than some type of a hardwood shim, Ligon said.

"It's unfortunate that this errant snag occurred late on a long holiday weekend when both the State of Vermont and the contractor are out until Tuesday," Ligon said.

Said Ligon in an email to this writer, "The bearing plates are 1" steel, with a large gusset welded in the center to accept the through bolts. The high heat produced during that welding process of thick steel made the large plates curl very slightly. That issue was addressed a year ago when the plates were delivered to the project, with no corrective action determined to be required. My interpretation of the conversation with Bill Flanders was that someone was concerned that the plates had bent due to the loading of the arch members."

With the inspection team unreachable, local authorities decided to open the bridge for the ceremony, allowing only one vehicle access at a time. The barriers would be replaced pending the outcome of the inspection.

Cambridge Junction Covered Bridge Opened

By Joe Nelson

Cambridge Junction, July 4, 2004 - At 8 a.m., on what turned out to be a perfect day for a celebration, the selectmen moved the Jersey Barriers away from the portals of the Cambridge Junction Bridge. The Barriers were moved back at the close of the ceremony. [See Inspection Results Iffy - Ed.]

The ceremony to celebrate the completion of the rehabilitation of the Junction Bridge, also known as the Poland Bridge, was opened by town resident William McKone, active in town affairs and member of the Cambridge Historical Society.*

A team of horses pulling a carriage loaded with celebrants was first to cross the bridge, preceded by a color guard of local two Scouts. The horses were followed by two antique cars and a motor cycle, all spaced out so that only one vehicle loaded the bridge at a time.

Kicking off the ceremony, McKone said: "The Cambridge Junction Covered Bridge has been rehabilitated and it's a beautiful job . . . its's been out of service for some ten years, now we have restored it and we hope it will be preserved for the future, its always the question of respecting the bridge and reading the signs...so there isn't any damage to the bridge in the future. I hope every body will enjoy it."

McKone went on to describe plans for the environs of the bridge. The town's green way is adjacent to the portal of the bridge, following the old railroad right-of-way. "The green way is intersecting with the bridge and it's going to be extended so there will be quite a recreation complex..." McKone said. "our intention is to use the sidings from the old Cambridge Junction railroad station to create a park, which we hope to name for Senator Jeffords who got us the money to restore this bridge as part of his national historic covered bridge preservation bill of some years ago.

"The state was kind enough to put together a sign for us commemorating this [bridge] and giving some information. I'm going to ask Stub Wells, who has been a long time resident to unveil the sign and say a few words about the bridge."

In the gathering of about 100 people were Senator Bartlett and Representative Rich Westman of the Vermont Legislature, town selectmen Dana Sweet, Frank Hutchins and Brad Blaisdell, and VTrans site engineer for the bridge William Flanders.

McKone introduced Wendell (Stub) Wells and Kate Westberg. Ms. Westberg, just graduated from St. Michael's College, did a journalism project on covered bridges. Stub Wells helped her with her research and provided her with some photos that went into the booklet she produced.

Said Kate Westberg: "The last time I was here, this isn't what the bridge looked like, so it's beautiful to finally see [it in this condition]. Stub Wells invited me, a stranger into his home and shared his knowledge and stories and history with me. This is one of the last copies [of the booklet] and I am giving it to you for keeping the Cambridge Junction [history alive]."

Stub received the booklet with thanks. The historic site sign was unveiled with some difficulty, as the masking blanket had been secured with duct tape against the breezes.

Said Stub Wells, "Bill has asked me to say a few words here, but I'm going to go back quite a ways, I'm going to turn the pages back on the old calendar eighty-five years. That is when I was brought up in Belvidere..."

Belvidere and Waterville are situated along the North Branch of the Lamoille River and because of this, travelers didn't have to go far before crossing a bridge. When Stub passed through an "arch" bridge he would wonder "What is that round thing along the side of the bridge?"

Stub was told, "Well, that is half of a wheel that holds up the bridge."

"I asked why isn't it underneath to hold up the bridge [and only] on top? He never explained to me why."

Stub described his travel through the bridges: "Then we came down to Belvidere Junction. We lived right at the end of the covered bridge and there, when the horses went through there, you could hear clippity-clop, clippity-clop, and I heard the same sound today with these horses. It was a wonderful feeling.

"Then you come down to Waterville and you entered another covered bridge. From Waterville then you came to the Town of Cambridge [and] the Marsh, what was called the George Marsh Bridge, I have traveled through many of these, many, many times.

"From the Marsh bridge we always came to Junction Bridge, better known as the Poland Bridge. Lots of times we had to stop when we came out here because back in those days they had three passenger trains that came up from Burlington. They had freight trains, they had milk trains. Then you had your trains from St. Johnsbury and Swanton. It was just fun to set here and watch these trains.

"But this bridge, back in the middle 1800s, the Town of Belvidere, the Town of Waterville, asked the selectmen of the Town of Cambridge if they would build a bridge here at Cambridge Junction, because they had to go down the other road to the [Bakersfield Road] and into the village and back up here with their lumber and whatever they put into boxcars. And it's two and two-tenths miles from the bend here, way around back to the bridge.

In 1885 Mr. Poland was retired from Washington as the congressman and then he owned land in Waterville and Belvidere, he owned the piece of land on the right as you cross the bridge. The selectmen of Belvidere and Waterville hired him, he was a lawyer, and he sued the Town of Cambridge and won the suite. But the Town of Cambridge didn't build the bridge until 1887.

"But Mr. Poland never lived to see this built, because he died right here of a heart attack in this little field.

"And then there were the years I started working for the McGovern store and I delivered feed to all the farmers up through here and I crossed this bridge about four or five times in a week. I always liked to see the design of them.

"I don't think there's anything else I can tell you about these bridges, but I always loved them in the olden days when I first started courting the girls."

Mr. Wells agreed, yes, he may have very well have started the tradition that covered bridges are kissing bridges.

* [Mr. McKone is also a member of the Vermont Covered Bridge Society but was not representing the VCBS in this affair.- Ed.]

Photo by Joe Nelson

July 4, 2004

Photo by Joe Nelson

July 4, 2004

Photo by Joe Nelson

July 4, 2004

Photo by Joe Nelson

July 4, 2004

Photo by Joe Nelson

July 4, 2004

Cambridge Junction Covered Bridge Opened to Light Traffic

Cambridge Junction, July 9, 2004 - Light traffic flows again over the Junction Bridge while discussions continued on the acceptance inspection results.

Because the acceptance inspection required to reopen the Cambridge Junction Bridge to traffic raised a question, it had been decided to open the bridge for the opening ceremony only, the town to replace barriers at the conclusion of the ceremony. See "Inspection Iffy" article below.

A last minute decision allowed the bridge to remain open. Said William Flanders, VAOT Site Engineer in an email: "The area in question was reinforced by the installation of hardwood blocks. This installation facilitated the bridge to remain open while discussions occur as to a permanent solution."

Poland Bridge Inspection Items Addressed by Alpine Construction Team

Cambridge Junction, August 24, 2004 - Jim Ligon and his team returned to the Poland Bridge this morning to address two items cited by the Vermont Agency of Transportation acceptance inspection: Voids in the abutments, and reinforcement of the Burr Arch bearing plates.

The Alpine team will force Portland cement into the abutments to fill any voids found and back the four bearing plates with grout.

Said Ligon in an email to this writer, "The bearing plates are 1" steel, with a large gusset welded in the center to accept the through bolts. The high heat produced during that welding process of thick steel made the large plates curl very slightly. That issue was addressed a year ago when the plates were delivered to the project, with no corrective action determined to be required. My interpretation of the conversation with Bill Flanders was that someone on the inspection team was concerned that the plates had bent due to the loading of the arch members."

A last minute decision allowed the bridge to open for the planned July 4th opening ceremony and to remain open. Said William Flanders, VAOT Site Engineer in an email: "The area in question was reinforced by the installation of hardwood blocks. This installation facilitated the bridge to remain open while discussions occur as to a permanent solution."

Traffic was permitted with the stipulation that only one vehicle at a time would be allowed on the bridge and a sign with this regulation was posted. Unfortunately, bridge users are either ignoring the sign or interpreting it to mean "One way traffic at a time only." Cars are streaming across at close intervals. In one instance, a large pick-up truck and laden trailer closely followed by a passenger car were seen to cross.

Photo by Joe Nelson

August 24, 2004

A form is placed around each of the four bearing plates to facilitate the introduction of grout between the plates and the abutment face. This is to prevent further flexing of the plate due to loading of the arches.

Drawing by Joe Nelson

August 24, 2004

The bearing plate receives the end of the Burr Arch. The tab accepts a through-bolt securing the arch to the bearing plate. The bearing plate is mounted on the abutment with threaded studs embedded in the concrete. The void behind the inch-thick plate was temporarily filled with a piece of hardwood, now to be replaced with grout.