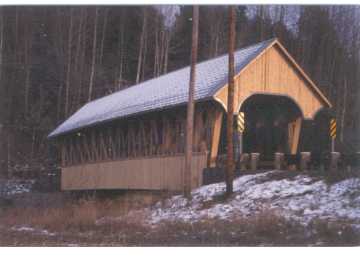

Irasburg's New Covered Bridge Opens to Traffic

WGN 45-10-02#2

The Irasburg Covered Bridge is open at last, connecting the towns of Irasburg and Coventry over the Black River. Governor Dean cut the ribbon in the early evening, Monday, November 29. The first person to officially cross the bridge was Roy Ingalls, long time Irasburg Selectman. He drove his pickup truck the final several feet out of the bridge through the south portal with Governor Dean as passenger.

With the sturdy timber used in the construction and the liberal application of fire-proofing chemicals, the new bridge can be expected to stand up well against time, traffic, and vandals.

All of Vermont's covered bridges are unique and each has a quirk of its own -- this one is no exception. John Weaver of the VAOT and the replica's designer pointed out that the original Irasburg Bridge was constructed with a fourteen-panel truss, the number of counties in the state of Vermont. Vermont, of course, was the fourteenth state to enter the union. The replica also uses a fourteen-panel truss.

The new bridge was built by Blow and Cote of Morrisville to replace the Orne covered bridge lost to arson on Halloween, November 1, 1997. The same firm reconstructed the Henry Bridge in North Bennington, and the Gates Farm Bridge in Cambridge. Dave Sargent of the Vermont Agency of Transportation is the construction engineer.

The trusses were laid out on the ground and there the hundreds of diagonal laps were cut across king posts, braces, and chords in the pattern typical of the Paddleford truss used in the original bridge. Square laps were cut for the doubled upper and lower chords as well. Those timbers, southern yellow pine, measure* 8.5 x 11 inches, the 15 king posts; 12 x 12, the braces; 10 x 10, and the counter braces; 4 x 8. Also, the counter braces are lapped into both sides of the truss instead of just one. This is no bridge for horse and buggy--it appears to be designed for whatever needs to cross over, with a generous margin of safety.

Carpenters Albert Lauzon of Coventry, Roland Blais of Newport, and Louie Fagnant of Arlington cut the laps with chainsaws and cleared the cuts with chisels. The huge timbers were moved into place with the aid of a fork-lift. The prerequisite "camber" was set by bending it into the chords prior to marking out the laps. When the first truss was completed, it was raised by crane into a standing position against a set of steel piles erected for the purpose. When the lifting slings were slacked off, said Fagnant, the truss lost only one-quarter inch of camber.

Asked how much the truss might weigh, Fagnant, estimating from the sum of the weights of the timbers, replied that the truss could weigh about 16 tons.

When the second truss was completed, the two trusses were placed over the river the modern way -- with a crane.

Fagnant noted that he had seen chisels used by an area carpenter bearing the initials J.D.C. - John D. Colton, the builder of the bridge being replaced, and probably the builder of the Paddleford bridge off Old Dump Road (now Covered Bridge Road). One of the antique chisels being used in the bridge restoration carries the initials "W.A.B."

Photo by Joe Nelson ©1999

Photo by Joe Nelson ©1999

Photo by Joe Nelson ©1999

Photo by Joe Nelson ©1999

Photo by Joe Nelson ©1999

[Editor's note: Text on this page ©1999, Joe Nelson

Photographs on this page ©1999, Joe Nelson